Rapid Non-destructive Headspace Gas Analysis for Permeation Studies

Tunable diode laser absorption spectroscopy (TDLAS) is a rapid and non-destructive analytical method suitable for monitoring gas concentrations and vacuum levels in the headspace of sterile product containers, pouches, or blisters. The characteristics of diode laser based measurement systems make them ideal for monitoring and controlling the gas concentration and (partial) pressure of common atmospheric molecules, such as oxygen and moisture, in primary packaging containers.

.

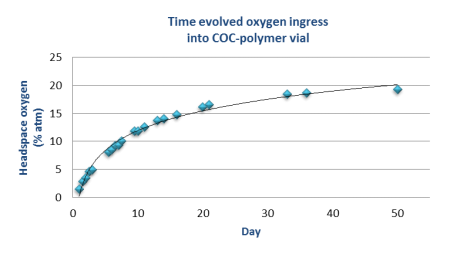

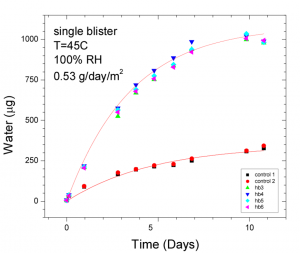

Among the many applications enabled by a rapid non-destructive headspace measurement are permeation studies of primary packaging material. One of the important objectives of the primary packaging material is to protect the drug formulation from compounds that could cause degradation of the active pharmaceutical ingredients. For sterile liquids, powders, freeze dried formulations, and solid dosage product this means protection against moisture (water vapor) and/or oxygen.

.

With an analytical technique that can rapidly and non-destructively quantify headspace gas conditions over time, it is possible to design permeation studies that give extensive insight into the quality of the packaging material. Such studies have been implemented for stoppers, blister material, pouches, and plastic containers. The non-destructive nature of the measurement saves samples that may be in limited supply and allows for the accurate monitoring of gas permeation in a single sample over time.

.