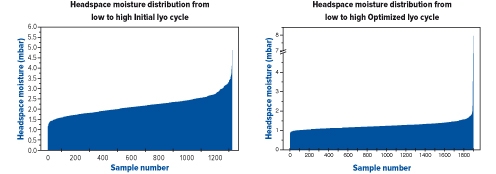

Lyo Cycle Optimization

The ability to efficiently optimize a lyophilization cycle depends partly on the ability to perform moisture analysis on finished product samples in an accurate and timely manner. This is traditionally done using Karl Fischer titration or thermo-gravimetric analysis (TGA) methods, which are destructive and labor & time intensive. Replacing these slow traditional methods with a rapid non-destructive method would streamline moisture analysis efforts and help to optimize freeze drying cycles quickly and efficiently.

.

Quantifying the amount of water vapor in the headspace of freeze-dried vials with an optical method enables rapid non-destructive moisture determination. Experiments have demonstrated that the amount of headspace water vapor directly correlates to the lyo cake moisture content. Stability studies have shown that the degradation of the active pharmaceutical ingredient correlates to the initial water vapor concentration present in the freeze-dried vial.

.

In primary drying heat transfer is affected by gaseous convection and conduction as well as the degree of shelf contact and evenness of heat applied. Therefore cycle length can be affected by vial location, degree of vial/(tray)/shelf contact, radiative heating, packing density, product formulation and the cycle conditions themselves. In order to investigate these parameters in detail, headspace moisture analysis can be used for moisture analysis of 100% of product which, in turn, gives deep insight into the process enabling quick and efficient process optimization.

.