100% inspection of pharmaceutical product

Upsets in production can impact a company’s ability to release product to market. Leasing an inspection platform to perform 100% container closure integrity (CCI) inspection of affected batches can avoid the costly decision to scrap valuable product.

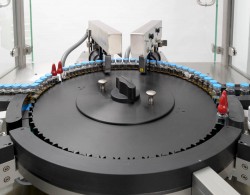

The PULSAR Headspace CCI Inspection Lease System is an automated 100% CCI inspection machine designed to inspect the CCI of sealed parenteral containers through the measurement of headspace oxygen and/or pressure. PULSAR characterizes the physical headspace conditions of a container in a single compact and flexible platform and is designed to address the following applications:

• 100% CCI inspection of freeze dried product having a vacuum or partial nitrogen pressure headspace

• 100% CCI inspection of modified headspace liquid and powder products

The PULSAR Headspace CCI Inspection Lease System is designed for quick configuration and can often be delivered and installed on site within a timeline of 12 weeks.

Headspace Laser Spectroscopy

The PULSAR Headspace Inspection System uses a patented laser-based detection method developed with funding from the Food and Drug Administration. Light from a near infrared laser is passed through a container in the region above the product and below the cap (headspace region). Diode laser sensors are designed to monitor the absorption wavelength of the headspace oxygen and moisture molecules to determine headspace concentrations of oxygen and moisture as well as the headspace pressure. Vials that have elevated levels of oxygen and/or pressure due to a leak can then be identified and rejected. This measurement method allows for the rapid analysis of 100% of product while reducing testing costs.

LIGHTHOUSE Instruments introduced the laser headspace technology into the pharmaceutical industry more than 15 years ago and has the largest installed base of laser-based headspace systems worldwide.