TECHNOLOGY: BACKGROUND AND MEASUREMENT PRINCIPLE

Background

Laser absorption spectroscopy is well established as an optical measurement method for rapid and non-destructive gas analysis. Beginning in 1998 Lighthouse Instruments pioneered the use of laser absorption spectroscopy for headspace gas analysis of pharmaceutical packages. The technique measures a number of physical parameters within the headspace of a pharmaceutical package, including gas concentration and total headspace pressure.

Light from a near-infrared semiconductor laser is tuned to match the internal vibrational frequency of a target molecule. The light is passed through the headspace region of a container, scanned in frequency and detected by a photodetector. The laser absorption signal contains information about the headspace gas concentration and total headspace pressure.

The measurement method incorporates a high sensitivity detection technique known as frequency modulation spectroscopy (FMS).

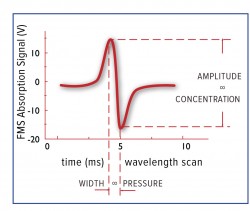

Measurement of Headspace Pressure

Absolute pressure or vacuum level in a pharmaceutical container can be measured by the pressure broadening of water vapor (moisture) absorption. Light from a tunable semiconductor laser is directed through the headspace region of a parenteral container. The laser light is tuned in frequency to match the internal absorption frequency of moisture molecules at 1382 nm. The width of the moisture absorption signal is proportional to total headspace pressure.

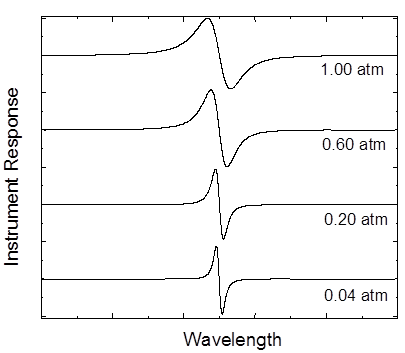

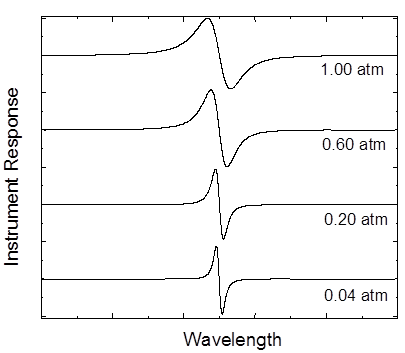

Figure 1 shows the moisture absorption signal broadening as the nitrogen pressure in the headspace of a 10cc vial increases from 0.04 atm to 1.0 atm.

Figure 1. Moisture absorption signals for vials with different headspace pressures. Each vial was prepared with constant moisture content (6% relative humidity) and a balance of nitrogen to the stated pressure. Note the signal width varies with pressure. The signal amplitudes are all normalized.

Measurement of Headspace Oxygen and Moisture Concentration

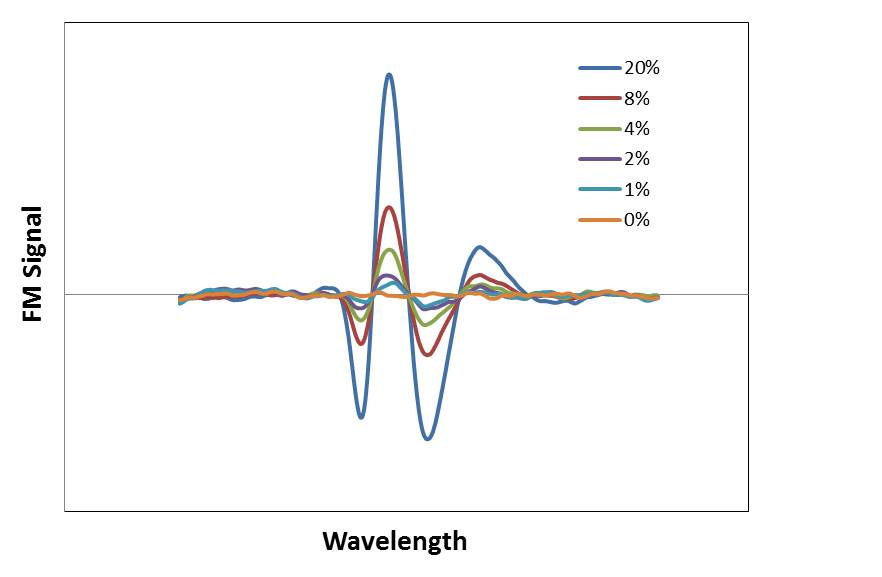

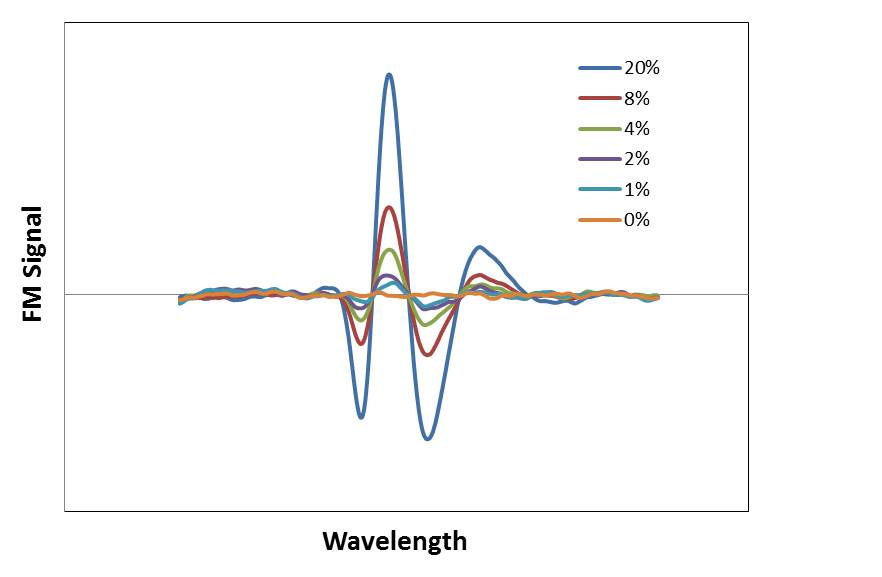

Gas concentrations can be measured in the headspace of pharmaceutical packages by laser absorption spectroscopy. Light from a tunable semiconductor laser is directed through the headspace region of a parenteral container. To measure moisture concentrations the laser light is tuned in frequency to match the internal absorption frequency of moisture molecules at 1382 nm. To measure oxygen concentrations the laser light is tuned in frequency to match the internal absorption frequency of oxygen molecules at 760 nm. The oxygen and moisture absorption signals are proportional to headspace gas concentration. Figure 2 shows the laser absorption signals for various amounts of oxygen in the headspace of 10cc vials.

Figure 2. Laser absorption signals from varying amounts of oxygen in a 10cc vial. The absorption signal is proportional to oxygen concentration (noted by the color coded legend).